Back to Main Page Back to Main Page

The Ford 8.8 axle is about 1 1/2" narrower than the stock ZJ Dana 44. It is a fairly noticeable difference, not only in looks, but in handling (it actually feels more "tippy" when turning). It also brought my tires too close to my sway bar to use snow chains. I hemmed and hawed about how to address this. I had 1.5" wheel spacers from when I had stock wheels, and I considered putting them on the rear and picking up some 1" spacers for the front. However, given that I already had wheels with minimal backspacing, I didn't really want to put any more stress on the ball joints than necessary. The Ford 8.8 axle is about 1 1/2" narrower than the stock ZJ Dana 44. It is a fairly noticeable difference, not only in looks, but in handling (it actually feels more "tippy" when turning). It also brought my tires too close to my sway bar to use snow chains. I hemmed and hawed about how to address this. I had 1.5" wheel spacers from when I had stock wheels, and I considered putting them on the rear and picking up some 1" spacers for the front. However, given that I already had wheels with minimal backspacing, I didn't really want to put any more stress on the ball joints than necessary.

Another option I considered was just picking up some 1/2" wheel spacer inserts (no bolts, just slots) from Ezaccessory, but this would have only left me with only about half the usual number of threads to secure my rear wheels. Granted, I could have put in longer lug studs to accomodate them, but I didn't care to get involved in that project. Besides, something about the whole idea just struck me as being a little unsafe. Call me paranoid, but I wanted to make sure that whatever I did bolted on.

|

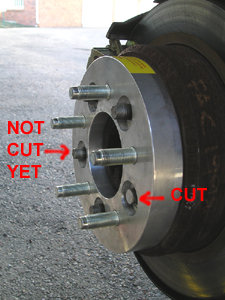

I finally settled on some 1" wheel spacers for the rear. Doing 3/4" would have made the front and rear axles equal width, but you can't really make a bolt-on wheel spacer that thin and still have it be sturdy enough. So I called the guys at Performance Wheel & Tire and ordered a pair of their billet-aluminum wheel spacers. They arrived about a week later. To make them fit however, I would need to trim about 1/4" off of the end of the lug studs so that the wheel would sit flat against the spacer. Not a big deal, since the part of the stud I needed to cut off wasn't even threaded.

I finally settled on some 1" wheel spacers for the rear. Doing 3/4" would have made the front and rear axles equal width, but you can't really make a bolt-on wheel spacer that thin and still have it be sturdy enough. So I called the guys at Performance Wheel & Tire and ordered a pair of their billet-aluminum wheel spacers. They arrived about a week later. To make them fit however, I would need to trim about 1/4" off of the end of the lug studs so that the wheel would sit flat against the spacer. Not a big deal, since the part of the stud I needed to cut off wasn't even threaded.

|

Below are the tools and equipment that I required to do this mini-project. I played it safe by having wheel chocks in front and behind the front tires in addition to having the rear axle resting on heavy duty jack stands (I'm plugging safety after hearing from a friend of mine how he was almost crushed recently when a jack stand slid out from under a vehicle).

Using a high-speed cutting tool run off of my air compressor, I cut off approximately 1/4" of the lug stud. It only took about a minute or so of cutting for each stud. Using a high-speed cutting tool run off of my air compressor, I cut off approximately 1/4" of the lug stud. It only took about a minute or so of cutting for each stud.

|

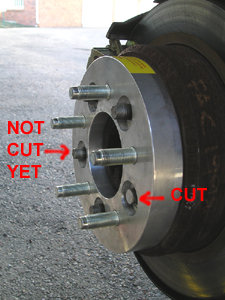

This picture shows the 1" wheel spacer in place with one of the lug studs cut so that the wheel can be flush on the wheel mounting surface. The remaining studs have not yet been cut. You can see how they protrude about 1/4" and why they need to be shortened. Notice that there was minimal loss of thread, giving me the option of going back to mounting my wheels without the spacers if I want without compromising safety. This picture shows the 1" wheel spacer in place with one of the lug studs cut so that the wheel can be flush on the wheel mounting surface. The remaining studs have not yet been cut. You can see how they protrude about 1/4" and why they need to be shortened. Notice that there was minimal loss of thread, giving me the option of going back to mounting my wheels without the spacers if I want without compromising safety.

|

Below is the wheel spacer bolted on with all of the lug studs cut. Again, notice how the nuts have plenty of thread. I torqued them to 90-100 lbs. I will check them periodically when I rotate my tires, but they aren't going anywhere. On the right is the ZJ with the wheels mounted on the new spacers in the rear. It looks much more even, and really does handle better on the road during turns. Not to mention that my chains will actually fit when I go snow wheeling this weekend!

ZJ build, continued

Back to Top Back to Top

Back to Main Page Back to Main Page

|

Back to Main Page

Back to Main Page

Back to Top

Back to Top